Collecting the Christmas spirit

Models with serial character, such as the MAN Christmas truck, are regarded as treasured keepsakes amongst collectors. Herpa Miniaturmodelle GmbH has been ensuring that this beautiful, festive truck makes it under the tree in good time since 2003.

Year after year, collectors and fans wait with baited breath for the new MAN Christmas truck. At this time of year, the glorious Christmas lion would normally be putting smiles on faces during dazzling appearances at Christmas markets, nursery schools and social institutions. But then again, everything has been done a little differently this year. Some things, however, never change: Even this year, the miniature version of the full-sized festive MAN truck will thrill each and every person who can call the coveted model their own. Herpa Miniaturmodelle GmbH has manufactured 2,550 units for MAN this year.

“MAN came up with the idea of having a real-life Christmas truck and a model version of it by themselves. They are one of our most loyal customers,” says a very pleased Matthias Wolff, Product Manager Cars & Trucks at Herpa. Every year, around 500,000 truck models – from tractor vehicles to complete semitrailer combinations – leave the “miniature forge” in Dietenhofen to put a smile on the faces of collectors around the world. The MAN Christmas truck has been part of the 71-year-old company’s product range for 17 years now. Every year, the truck has a new design and features the latest MAN tractor vehicle. “These are sought-after models and they are sold exclusively by MAN,” reveals Matthias Wolff.

“The finesse and experience of our employees are our most valuable assets.”

Matthias Wolff

Christmas starts in August

Herpa starts the intricate production process in the summertime so that the Christmas truck is ready to roll in time for the festive season. By the time the miniature truck is complete, all 200 employees of the company will have been involved in the various work steps in some way. “Great attention to detail” is a key feature of every single work step: “The finesse and experience of our employees are our most valuable assets,” says Wolff. At all times, everyone strives to achieve the best possible outcome. “Our designers are constantly faced with huge challenges that they have to overcome,” says the Product Manager, talking about the demanding manufacturing process.

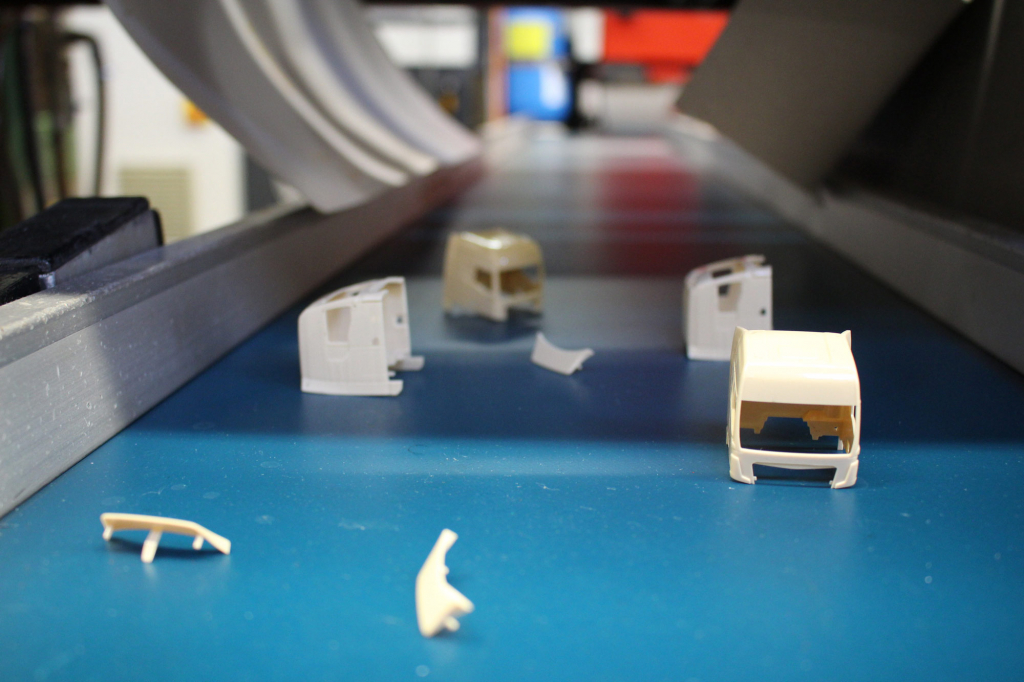

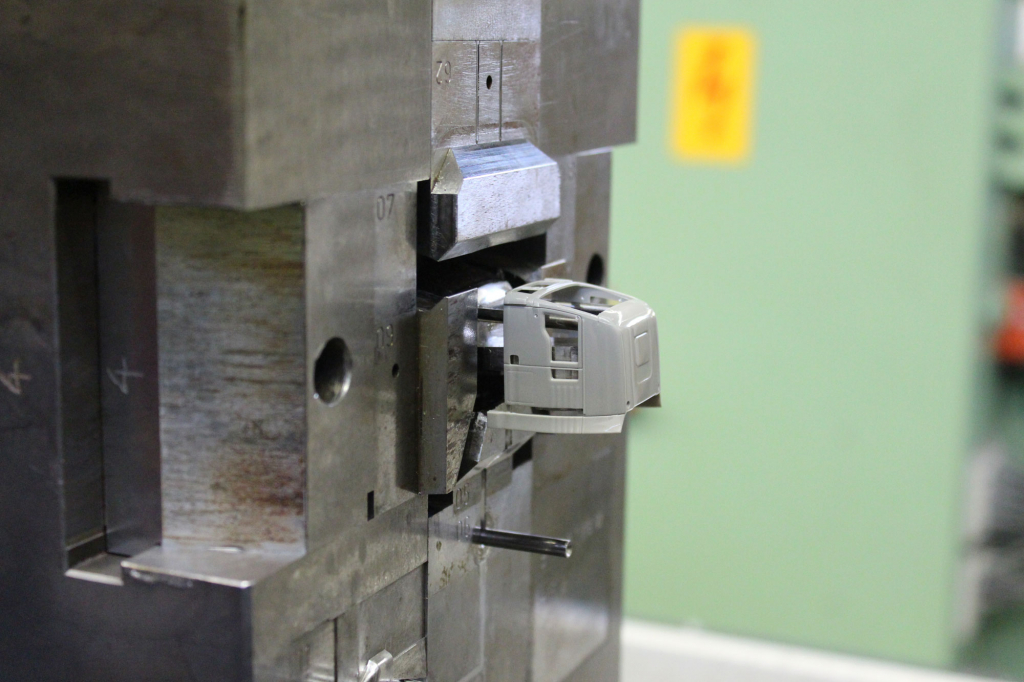

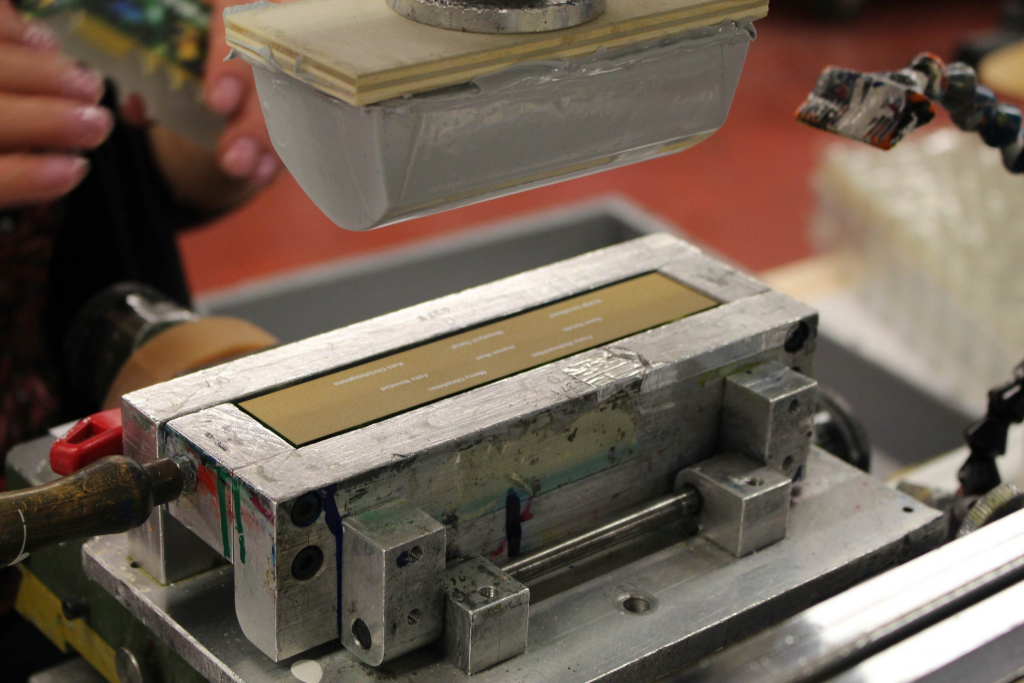

Once the individual in charge has talked with the customer in detail about what the MAN Christmas truck should look like, we can start with the plastic injection moulding process for the individual components using the colours selected. At the same time, the graphics department produces the films required for the vehicle decals. This pertains to the print film for an indicator light on the mudguard and also for a raster image on the luggage compartment. All of the parts to be printed are brought from the injection moulding shop to the print ship. This is where the individual parts are printed. All of the parts of the model are pieced together in the homework department: The tractor vehicle and semitrailer of the Christmas truck are assembled separately by different homeworkers at this stage. It is only at the final assembly stage that they are joined together and packaged. After a final quality inspection, the festive models are sent to MAN in mid-November before they are finally handed over to excitable customers.

This is your chance!

Amongst collectors, the term “complete” means that you own all of the models in a series. To keep that up, a collector needs to get hold of the latest MAN Christmas truck with every passing year. That means acting swiftly when the opportunity presents itself.

The MAN Christmas truck is of course available in the MAN Merchandise Shop.