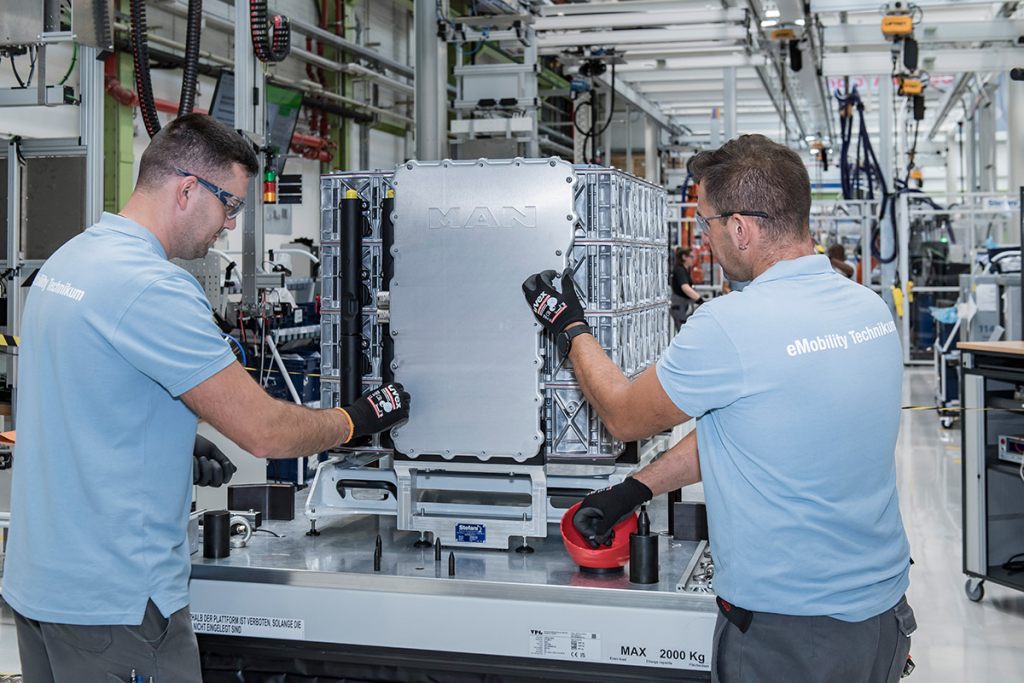

MAN battery production

As of 2025, the MAN Nuremberg site will start producing 100,000 high-voltage batteries every year – a milestone on the brand’s path to becoming a provider of sustainable and eco-friendly transport solutions.

Trucks produce some 27% of the annual CO2 emissions found on Europe’s roads.* The responsibility shouldered by our industry to help combat climate change is correspondingly huge. MAN is working at full speed to face the transport revolution head on, by utilising ever more efficient engines and CO2-saving measures in production processes. These initiatives are accompanied by a gradual transition to economical zero-emission vehicles: 2020 saw the MAN Lion’s City E electric city bus ready to hit the production line, while the new MAN eTrucks will start being rolled out to customers in 2024. And not forgetting high-voltage batteries for MAN e-vehicles: These will roll off the production line at the Nuremberg site as of 2025. MAN plans to transform the site into an innovation and production centre for alternative drives. In-house MAN battery production offers a host of benefits, as explained by MAN expert Michael Bernath, Head of Battery Development: “By producing batteries in-house, it enables us to have a constant overview of all the different battery components as well as to guarantee MAN’s high standards of quality during every stage of production. We have consolidated the Engineering, Development and Production departments under one roof at Nuremberg. This approach allows us to utilise the short distances to help overcome any challenges quickly and efficiently and to implement optimisation measures on site.”

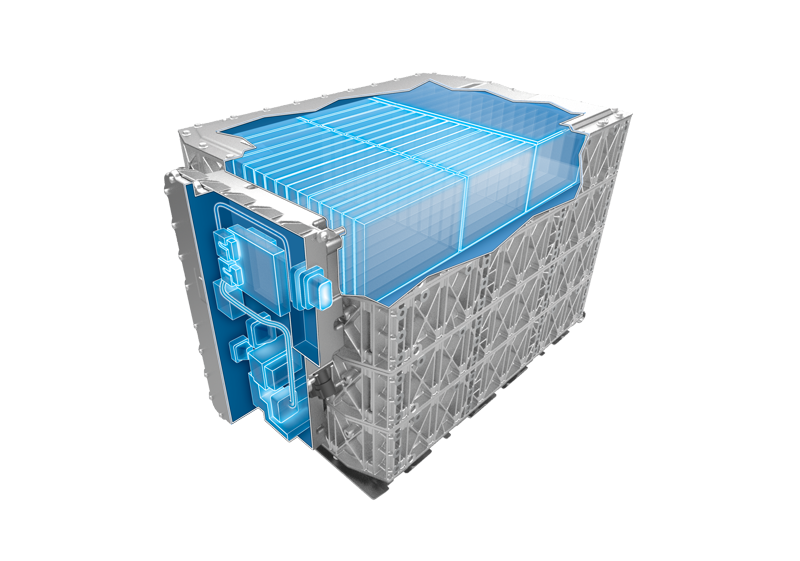

New battery technology from MAN

The future powerhouse of MAN eTrucks and eBuses is approximately the size of a refrigerator and weighs several hundred kilograms. In principle, each battery has the same structure: The smallest unit is the cell. These cells are combined into modules or stacks. The modules are then assembled in a pack and connected electrically. The cells or modules can be connected in parallel and/or in series, depending on the number of cells and the required voltage level. Michael Bernath continues:

“The batteries are tailor-made for our trucks and buses, thereby enabling them to be integrated to maximum effect.”

“They only differ in terms of the pack design. With our modular approach, it is possible to choose between different configurations, depending on how much range or installation space for bodies is required.”

Setting up the charging infrastructure – a key factor

High-voltage batteries already achieve daily ranges of 600 to 800 km in electric trucks, meaning that many areas of application are already covered. In the future, the target is to achieve possible daily ranges of over 1,000 km. The new MAN eTrucks will therefore be fully compatible with long-haul transport. In addition, those responsible at MAN are working on setting up the charging infrastructure, which is a key factor in making the switch to electric mobility compatible with everyday life. To make it easy for you to “refuel” on the road, the TRATON GROUP (which MAN is part of) has established a joint venture with Daimler Truck and the Volvo Group. The goal of the Milence joint venture is to set up and operate more than 1,700 high-performance charging points for green electricity on and near motorways as well as at logistics hubs in Europe. Michael Bernath adds:

“MAN is also advising individual transport companies on the planning and implementation of their own charging strategies.”

MAN is driving change. By as early as 2030, around 50% of all newly registered MAN trucks will be battery powered. You never know: Your company may soon be on the road fuelled by new power from Nuremberg.

You can find more information about the MAN battery here on the website.

Note: * https://www.destatis.de/Europa/DE/Thema/Umwelt-Energie/CO2_Strassenverkehr.html